MCP-4 for Silicon-Carbon Anodes

This case study was conducted by a silicon-carbon anode materials manufacturer to evaluate Momentum Materials’ MCP-4 as a carbon support for silicon. The study was completed in 2025.

Silicon’s Role in Pushing Battery Capacity Limits

Silicon anodes are a promising alternative to conventional graphite anodes for lithium-ion batteries. Silicon has a much higher theoretical capacity than graphite (4200 mAh/g vs. 372 mAh/g), but its practical use is limited by severe volume expansion during charge-discharge cycling.

Depositing silicon within a mesoporous carbon skeleton effectively mitigates this swelling while providing a continuous conductive network, thereby extending the cycle life of silicon–carbon anodes.

Momentum Materials®: 3D Interconnected Mesoporous Carbon

Momentum Materials’ MCP-4 features a narrowly distributed pore size centered at ~4 nm, enabling uniform silicon deposition and consistent electrochemical performance in silicon–carbon anodes.

Chemical vapor deposition (CVD) is typically used to deposit silicon into mesoporous carbon structures. The deposited silicon particles are usually 2–3 nm in size and expand to ~1.5x during cycling. The 4 nm pores of MCP-4 effectively confine the silicon and prevent carbon wall rupture.

The three-dimensional, interconnected porous network of MCP-4 ensures good electronic conductivity and eliminates the need for complex silicon surface treatments or prelithiation.

Scope and Objectives

This case study aimed to validate the applicability of chemical vapor deposition of silicon into MCP-4 and to evaluate the electrochemical performance of the resulting silicon–carbon composite (Si@MCP-4) as an anode material.

Key objectives included:

- Evaluating MCP-4 as a mesoporous carbon skeleton for silicon deposition

- Assessing the electrochemical performance of Si@MCP-4 as an anode

Anode performance was evaluated in a half-cell configuration using Si@MCP-4 as the working electrode and lithium metal as the counter electrode.

Results

Characterization of MCP-4

Scanning electron microscopy (SEM) images of MCP-4 are shown in Figure 1. The material consists of fine powders with a rough carbon surface, resembling carbon derived from coconut shells.

Figure 1 – SEM images of MCP-4 at different magnifications

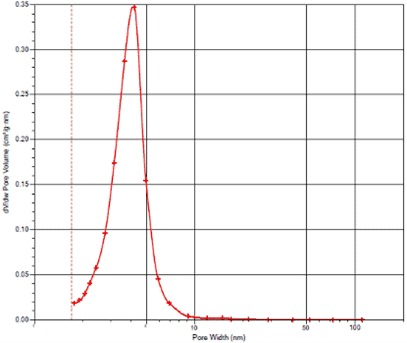

The porous structure of MCP-4 was evaluated by nitrogen physisorption, and the results are summarized in Table 1. MCP-4 exhibits a surface area greater than 900 m2/g with a very narrow pore size distribution centered around 5 nm (Figure 2). Given that the BJH model can introduce a 10–30% error for small mesopores, seeing a pore size around 3-5 nm is reasonable.

Particle size distribution measured by dynamic light scattering and tap density are summarized in Table 2. MCP-4 shows a relatively wide particle distribution.

Figure 2 – Pore size distribution of MCP-4

Table 1 – Summary of porous characterization of MCP-4

| SBET (m2/g) | Pore volume (mL/g) | <0.5 nm | 0.5-1.0 nm | 1.0-2.0 nm | 2.0-10 nm | >10 nm | Average pore size (nm) |

|---|---|---|---|---|---|---|---|

| 920.82 | 1.14 | 0 | 0 | 0 | 98.88% | 0 | 5.24 |

Table 2 – Particle size distribution and tap density of MCP-4

| D10 (µm) | D50 (µm) | D90 (µm) | D97 (µm) | D99 (µm) | D100 (µm) | Tap density (g/ml) |

|---|---|---|---|---|---|---|

| 1.48 | 4.75 | 13.5 | 20.6 | 26.4 | 39.7 | 0.2407 |

Evaluation of the Si@MCP-4 Material

Around 66 wt.% silicon was deposited into MCP-4. Subsequently, an additional 1wt.% carbon was deposited via CVD to seal the entrance pores. The physical and surface properties of Si@MCP-4 are summarized in Table 3.

Table 3 – Composition and Properties of Si@MCP-4

| Carbon (wt.%) | Oxygen (wt.%) | Resistivity @10MPa (Ω·cm) | SBET (m2/g) | Pore volume (mL/g) |

|---|---|---|---|---|

| 32.48 | 1.14 | 413.5 | 18.25 | 0.04 |

A coin cell assembled with Si@MCP-4 and lithium metal was used to evaluate the performance of the Si@MCP-4 anode. Cyclic voltammetry and charge–discharge curves are shown in Figure 3. The c-Li3.75Si delithiation peak (~0.45 V vs. Li+/Li) is present but not pronounced. Silicon lithiation plateaus appear at around 0.2 V and 0.06 V.

The specific capacity at 0.8 V is 2420 mAh/g, with an initial Coulombic efficiency of 85.4%. At 1.5 V, the specific capacity reaches 2630 mAh/g with an initial Coulombic efficiency of 93.0%.

Figure 3 – Cyclic voltammogram (left) and charge-discharge profiles (right) of Si@MCP-4 in a half-cell.

Conclusions

This case study demonstrates that MCP-4 is a suitable carbon support for silicon. The resulting Si@MCP-4 anode delivers very high specific capacity in a half-cell configuration. Further validation in full cells and larger-format cell configurations is currently underway.